One of the aspects that PMW follow with interest is the design of custom parts for rig modifications, deck hardware and for power boats.

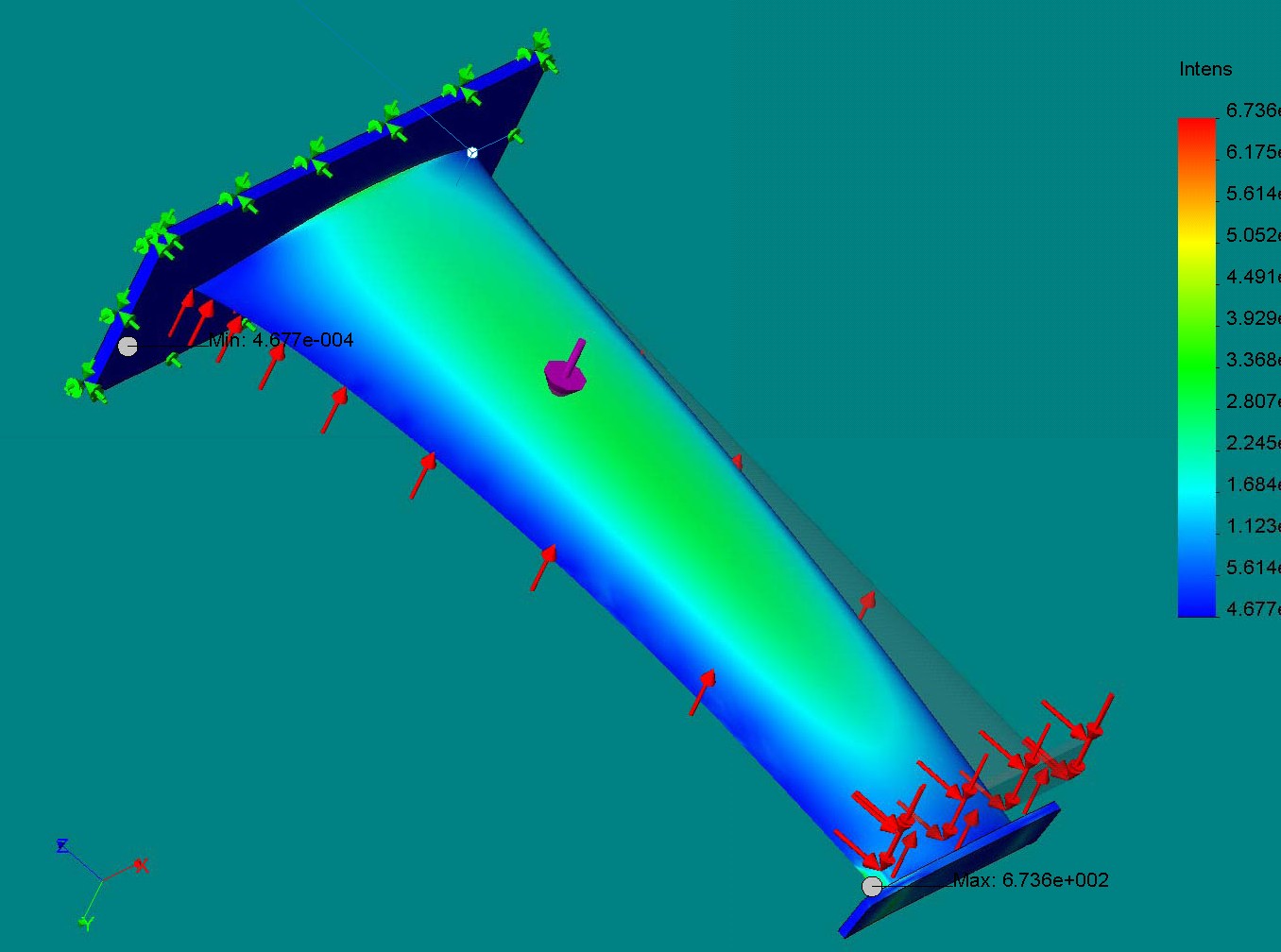

For custom parts design we use our in house FEM calculation, as we are confident about the geometries, the loads and the results. We use it for keel design, rudder stock design, bowsprit, chainplates design and other interesting parts. The first step is to visit the boat and test the problem that has to be solved with our work; when the problem is clear we start the brainstorm around it and arrive at a number of geometries that will be checked both with FEM to obtain the structural response to the theoretical loads, and to the manufacturer in order to value the costs-reliability ratio. When we're sure of the optimal geometry we start the construction drawings and we follow the fitting out of the part on the boat, to be sure that any eventual mounting problem can be solved easily.

In the last years we custom designed keels, tender lift mechanisms, transom doors, rudders, anchor's systems, outboard appendages for power boats, etc...